FDA food-grade storage environments

Commonwealth considers the food & beverage industry one of its core specialties because we have handled so much of it throughout our history. We understand the realities of a high volume / high velocity business scope typical of the food & beverage industry. We have the experience and the flexibility required to properly manage a client’s business in this sector.

We have experience with a wide variety of commodities including but not limited to:

- Coffee (bottled & raw)

- Beer & Alcoholic drinks

- Carbonated drinks

- Energy Drinks

- Bottled Water

- Tea (loose leaf & bagged)

- Meals Ready-to-Eat (MRE)

- Fruit juices

- Shortening & Raw Materials

Food Grade Storage

All of our warehouses are registered with the FDA providing food-grade storage environments to our food & beverage clients. We maintain high sanitation protocols in adherence with FDA, GMP, ASI, and US Military standards. Our quality team has implemented a detailed HAACP program to manage potential hazards and control points for food grade materials. Our buildings are also monitored for pest and rodent activity by Orkin, the nation’s top pest control system provider. All Commonwealth employees receive annual training on the proper ways to safely store and handling food products.

EDI Inventory Tracking

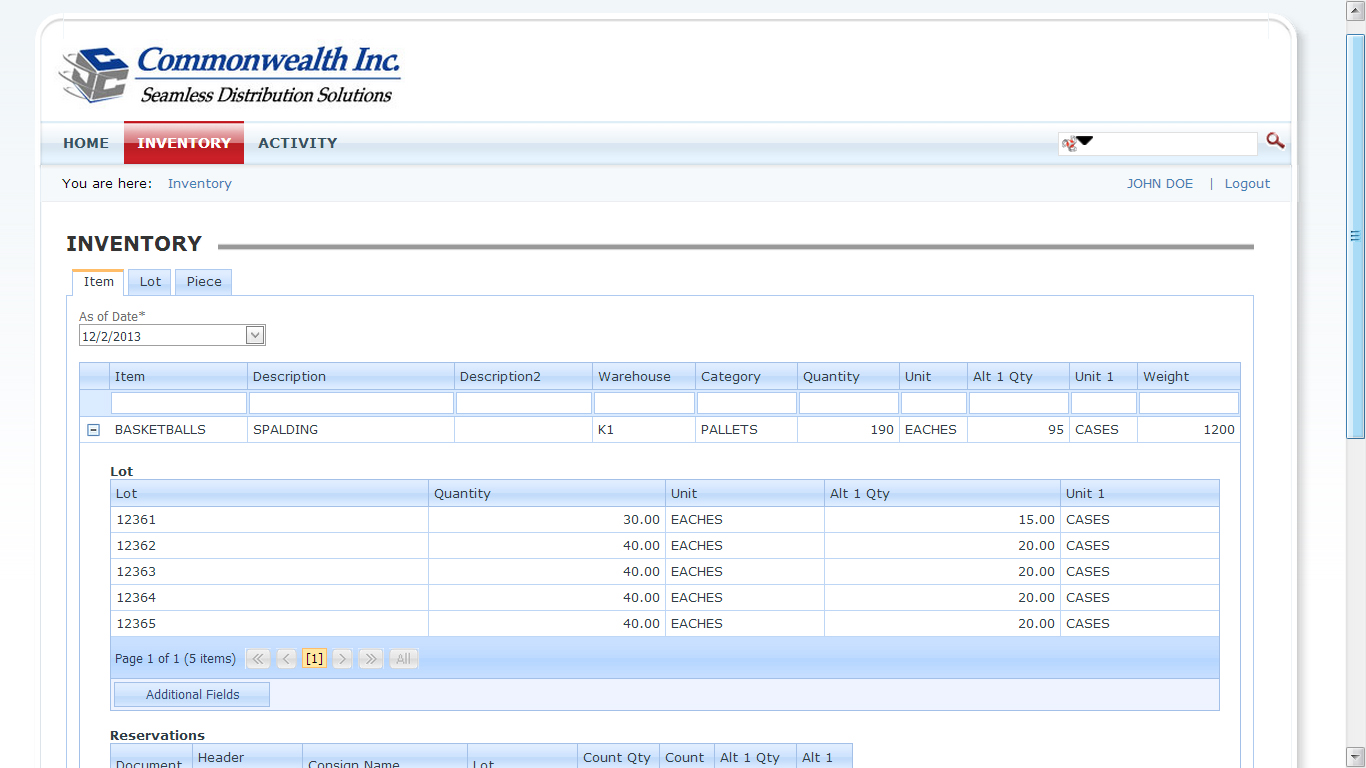

Our WMS 3Plink plays an important role in properly managing food & beverage accounts. First and foremost it automatically regulates FIFO shipping protocols to ensure proper stock rotation. 3PLink also provides batch and lot control when products are in storage and historically in the event of a recall. Inventory levels are monitored using up to three different units of measure. Such detail allows our clients to know exactly what they have on-hand down to the individual unit level using our Web Portal service.

Value-Added Services

Many of our food & beverage customers ask us to convert stock into POP displays, variety packs, and other configurations for seasonal promotions. Our warehouseman have completed dozens of value-added projects like this and have the experience necessary to do the job right. Below is a video of a variety repack and shrink wrap project we completed for Starbucks.